Powder Coating Vs. Anodizing

Dive into the realm of Powder Coating Vs. Anodizing. Uncover the distinctions between these metal finishes, exploring processes, applications, and important differences in this informative article.

Powder coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder.

The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form.

The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a “skin”. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint.

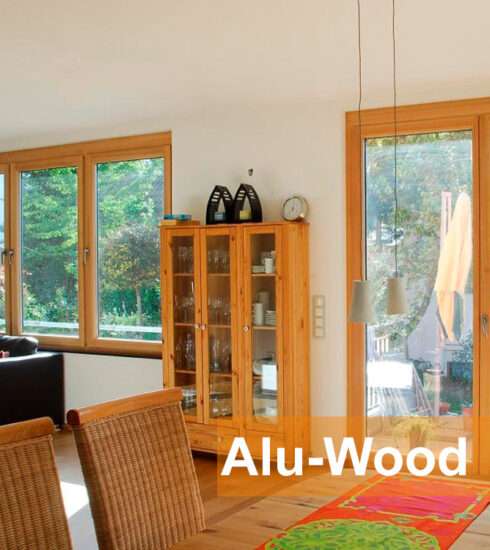

Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, and automobile and

bicycle parts. Newer technologies allow other materials.

Here are few Pros and Cons of Powder Coating

Pros: Powder coating provides a long-lasting, economical, and durable finish with a range of color options available for Aluminium metal. A powder coated frame will be more resistant against scratches, chipping, wear, and fading compared to other type of finishes.

You can choose from an almost unlimited selection of colors, including, glossy, high-gloss, flat, fluorescent, candies, clear, hammer toned, iridescent, glitter and wrinkle.

Read: Popular Powder Coated RAL Colors

Cons: Can deteriorate from UV light – As with any coating, over time, there will be gradual fading. However, there are additional UV protective coats that can be applied to mitigate this.

Coats are thick. Do not expect extremely thin coats.

Anodizing

Anodizing (UK: Anodising) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts.

Anodizing is accomplished by immersing the aluminum into an acid electrolyte bath and passing an electric current through the medium. A cathode is mounted to the inside of the anodizing tank; the aluminum acts as an anode, so that oxygen ions are released from the electrolyte to combine with the aluminum atoms at the surface of the part being anodized. The process is called “anodizing” because the part to be treated forms the anode electrode of an electrical circuit.

Here are few Pros and Cons of Anodizing

Pros: Anodizing increases corrosion resistance and wear resistance, and provides better adhesion.

In general anodizing is less expensive than painting with the exception of coil painted products.

Anodizing is harder than PVDF. Anodizing is better for Aluminium in high traffic areas where the coating is subject to physical abuse and abrasive cleaners.

Anodizing cannot peel off. The coating is actually part of the metal.

Anodizing gives aluminium a deeper, richer metallic appearance than is possible with organic coatings.

Anodizing is unaffected by sunlight. All organic coatings will eventually fail due to exposure to ultra-violet light.

Cons: Limited colour options. Costlier than Powder Coating, No Warranty, Touch-ups are more noticeable Specially Joints and Corners.

Read more about Powder Coating, By Visiting: www.powdercoating.org

Read more about Anodizing, By Visiting: www.anodizing.org